OCA (Optically Clear Adhesive), optical adhesive, is a special adhesive used for bonding transparent optical components (such as lenses, etc.). With colourless transparency, light transmission rate of more than 90%, good bonding strength, can be cured at room temperature or medium temperature, and curing shrinkage and other characteristics. Simply put, OCA is an optically transparent layer of special double-sided adhesive! So what are the advantages and disadvantages of OCA?

OCA lamination industrial display advantages:

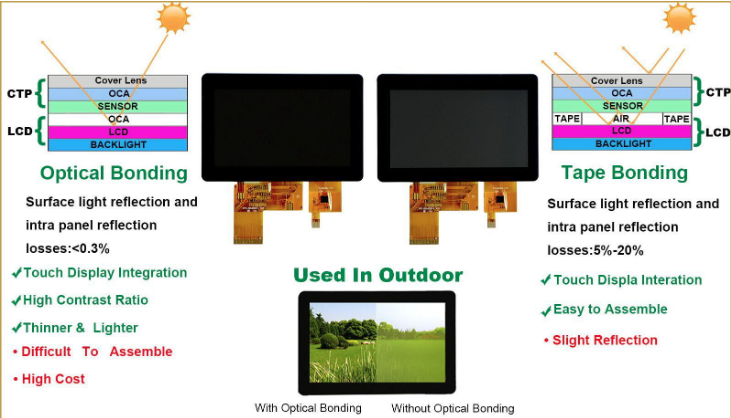

1. Reduce glare, reduce the loss of light emitted from the industrial display, increase the brightness of the industrial display and provide high transmittance, reduce energy consumption;

2. Increase contrast, especially under strong light exposure;

3. Higher strength for the whole surface connection;

4. Newton's rings can be effectively avoided;

5. Flatter product surface;

6. No boundary, expanding the viewing area;

OCA lamination industrial display disadvantages:

1.OCA adhesive film surface with sticky, easy to leave marks on the surface when peeling off the release film, easy to produce bubbles when laminating, need to use a special machine to remove bubbles. Easy to adsorb dust and impurities causing secondary pollution.

2.OCA and sensor lamination process, manual paste pressure is not uniform, easy to wrinkle bubbles.

3.OCA has poor fluidity performance, it is difficult to fill the groove of ITO line or ink when it is laminated to the sensor or cover glass.

4. OCA bonding performance is not strong, good product lamination, there is a risk of rebound.

5.OCA lamination is more costly than foam adhesive lamination.