Capacitive touch panels have become an integral part of modern technology, revolutionizing the way we interact with electronic devices. As a leading touch panel supplier, I am excited to delve into the fascinating world of capacitive touch panels and explain how they work.

The Basics of Capacitive Touch Technology

At its core, a capacitive touch panel operates on the principle of capacitance. Capacitance is the ability of a system to store an electric charge. In a capacitive touch panel, a layer of conductive material, typically indium tin oxide (ITO), is applied to the surface of a glass or plastic substrate. This conductive layer forms a capacitor with the human body, which is also a conductor of electricity.

When a user touches the surface of the capacitive touch panel, the human body's electrical charge interacts with the conductive layer, causing a change in the capacitance at the point of contact. This change in capacitance is detected by the touch panel's controller, which then calculates the exact location of the touch and sends this information to the device's operating system.

Types of Capacitive Touch Panels

There are two main types of capacitive touch panels: surface capacitive and projected capacitive.

Surface Capacitive Touch Panels

Surface capacitive touch panels are the simpler and less expensive of the two types. They consist of a single layer of conductive material, usually ITO, applied to the surface of a glass or plastic substrate. Four electrodes are placed at the corners of the panel, which are used to measure the change in capacitance when a touch occurs.

When a user touches the surface of a surface capacitive touch panel, the electrical charge from the human body is distributed across the conductive layer. The change in capacitance is detected by the electrodes at the corners of the panel, and the controller calculates the location of the touch based on the relative changes in capacitance at each electrode.

Surface capacitive touch panels are suitable for applications where multi-touch functionality is not required, such as ATMs, kiosks, and industrial control panels. However, they are not as accurate or responsive as projected capacitive touch panels, and they can be affected by environmental factors such as moisture and dirt.

Projected Capacitive Touch Panels

Projected capacitive touch panels are more advanced and expensive than surface capacitive touch panels. They consist of two or more layers of conductive material, usually ITO, separated by a dielectric layer. The conductive layers are patterned into a grid of rows and columns, which allows for the detection of multiple touches simultaneously.

When a user touches the surface of a projected capacitive touch panel, the electrical charge from the human body creates a disturbance in the electrostatic field between the conductive layers. This disturbance is detected by the touch panel's controller, which then calculates the exact location of each touch based on the changes in capacitance at each intersection of the rows and columns.

Projected capacitive touch panels are highly accurate and responsive, and they can support multi-touch gestures such as pinch-to-zoom and swipe. They are also more resistant to environmental factors such as moisture and dirt, making them suitable for a wide range of applications, including smartphones, tablets, laptops, and touchscreen monitors.

How Capacitive Touch Panels are Manufactured

The manufacturing process of capacitive touch panels involves several steps, including substrate preparation, conductive layer deposition, patterning, and assembly.

Substrate Preparation

The first step in the manufacturing process is to prepare the substrate, which is usually made of glass or plastic. The substrate is cleaned and polished to remove any impurities or defects that could affect the performance of the touch panel.

Conductive Layer Deposition

The next step is to deposit the conductive layer, usually ITO, onto the surface of the substrate. This is typically done using a process called sputtering, which involves bombarding a target material with high-energy ions to release atoms that then deposit onto the substrate.

Patterning

After the conductive layer has been deposited, it is patterned into the desired shape using a photolithography process. This involves applying a photosensitive resist to the conductive layer, exposing it to ultraviolet light through a mask, and then developing the resist to remove the unwanted areas of the conductive layer.

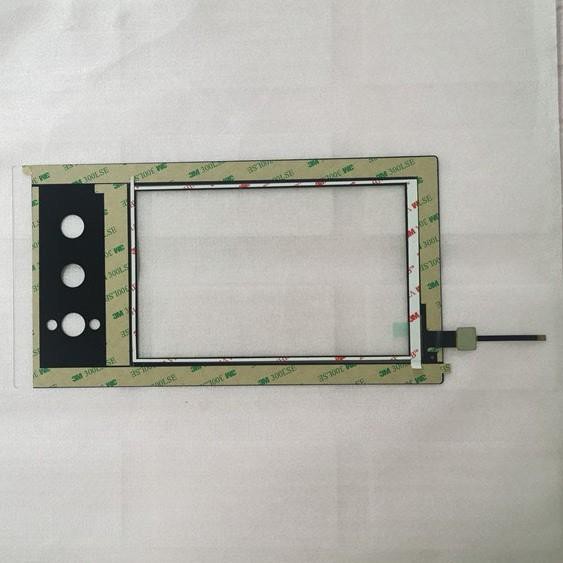

Assembly

The final step in the manufacturing process is to assemble the touch panel by attaching the controller and other components to the patterned conductive layer. The touch panel is then tested to ensure that it meets the required specifications and performance standards.

Advantages of Capacitive Touch Panels

Capacitive touch panels offer several advantages over other types of touch panels, such as resistive touch panels.

High Sensitivity and Responsiveness

Capacitive touch panels are highly sensitive and responsive, allowing for precise and accurate touch input. They can detect even the lightest touch, making them ideal for applications where fine control is required, such as drawing tablets and gaming devices.

Multi-Touch Functionality

Projected capacitive touch panels support multi-touch functionality, which allows users to perform gestures such as pinch-to-zoom, swipe, and rotate. This makes them more intuitive and user-friendly than other types of touch panels, and it has revolutionized the way we interact with electronic devices.

Durability and Reliability

Capacitive touch panels are more durable and reliable than other types of touch panels, as they have no moving parts and are less prone to wear and tear. They are also more resistant to environmental factors such as moisture and dirt, making them suitable for use in harsh environments.

Aesthetics

Capacitive touch panels have a sleek and modern appearance, which can enhance the overall aesthetics of a device. They are also available in a variety of sizes and shapes, making them suitable for a wide range of applications.

Applications of Capacitive Touch Panels

Capacitive touch panels are used in a wide range of applications, including consumer electronics, industrial control panels, automotive displays, and medical devices.

Consumer Electronics

Capacitive touch panels are the most common type of touch panel used in consumer electronics, such as smartphones, tablets, laptops, and touchscreen monitors. They have become the standard input method for these devices, offering a more intuitive and user-friendly experience than traditional input methods such as keyboards and mice.

Industrial Control Panels

Capacitive touch panels are also used in industrial control panels, where they provide a more reliable and durable input method than traditional mechanical buttons and switches. They are resistant to environmental factors such as moisture and dirt, making them suitable for use in harsh industrial environments.

Automotive Displays

Capacitive touch panels are increasingly being used in automotive displays, such as infotainment systems and instrument clusters. They offer a more intuitive and user-friendly interface for drivers, allowing them to control various functions of the vehicle with a simple touch.

Medical Devices

Capacitive touch panels are also used in medical devices, such as patient monitors and diagnostic equipment. They provide a hygienic and easy-to-clean input method, which is essential in a medical environment.

Conclusion

Capacitive touch panels have revolutionized the way we interact with electronic devices, offering a more intuitive and user-friendly experience than traditional input methods. As a leading touch panel supplier, we are committed to providing our customers with high-quality capacitive touch panels that meet their specific needs and requirements.

If you are interested in learning more about our capacitive touch panels, or if you have any questions or inquiries, please feel free to contact us. We would be happy to discuss your project with you and provide you with a customized solution.

For more information on our products, you can visit the following links:

- 8 Inch Capacitive Touch Screen For POS

- 8.4 Inch Touch Screen Panel

- 8 Inch Industrial Capacitive Touch Screen

References

- "Capacitive Touch Screens: How They Work and Why They're So Popular." How-To Geek, 2021.

- "Touch Screen Technology: A Comprehensive Guide." TechTarget, 2021.

- "Capacitive Touch Panel Market Size, Share & Trends Analysis Report by Type, by Application, by Region - Global Forecast to 2026." Grand View Research, 2021.