As a touch panel price supplier, I've received numerous inquiries regarding the pricing of outdoor - use touch panels. A common question that arises is whether touch panel prices are higher for outdoor - use models. In this blog, I'll delve into the factors that contribute to the cost of outdoor touch panels and compare them with their indoor counterparts.

Understanding the Basics of Touch Panel Pricing

Before we analyze the price differences between outdoor and indoor touch panels, it's essential to understand the basic components that influence touch panel pricing. The cost of a touch panel is determined by multiple factors, including the size, technology, materials, and manufacturing process.

Size is an obvious factor. Larger touch panels generally cost more than smaller ones because they require more materials and more complex manufacturing processes. For example, an 8 Inch Industrial Capacitive Touch Screen will be more expensive than a 4 - inch one due to the increased surface area.

The technology used in the touch panel also plays a significant role. There are different types of touch technologies, such as resistive, capacitive, and infrared. Capacitive touch panels, which are more sensitive and offer multi - touch capabilities, are often more expensive than resistive touch panels.

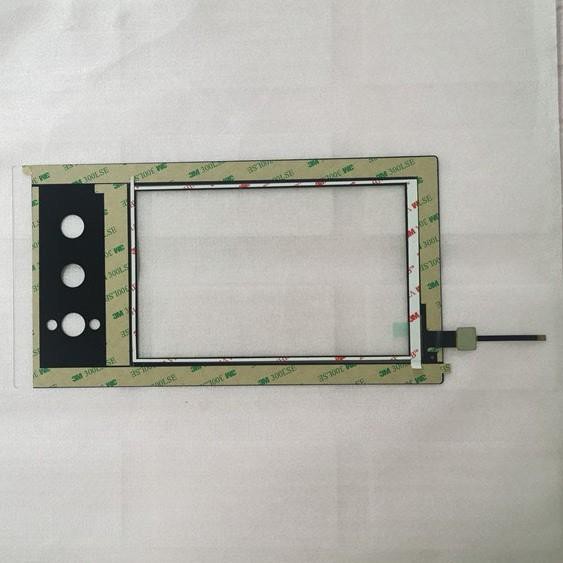

Materials are another crucial aspect. High - quality materials, such as strengthened glass for the screen surface, will increase the cost. The manufacturing process can also add to the price. More precise and advanced manufacturing techniques, such as those used for high - resolution touch panels, will drive up the cost.

Why Outdoor - Use Touch Panels May Be More Expensive

Now, let's focus on why outdoor - use touch panels might have a higher price tag.

Environmental Resistance

One of the most significant differences between outdoor and indoor touch panels is their ability to withstand harsh environmental conditions. Outdoor touch panels need to be resistant to extreme temperatures, humidity, sunlight, and dust.

Extreme temperatures can affect the performance of touch panels. In very cold conditions, the touch panel's responsiveness may decrease, while in high - temperature environments, the materials can expand, leading to potential malfunctions. To ensure reliable operation in a wide temperature range, outdoor touch panels are often equipped with special heating or cooling systems, which adds to the cost.

Humidity is another challenge. Moisture can seep into the touch panel and damage its internal components. Outdoor touch panels are designed with waterproof and moisture - resistant materials, such as sealed enclosures and hydrophobic coatings on the screen surface. These protective measures increase the production cost.

Sunlight can also pose a problem. The strong sunlight outdoors can cause glare on the touch panel, making it difficult to see the screen. To combat this, outdoor touch panels use anti - glare and anti - reflection coatings. These coatings are more complex and expensive to apply compared to regular coatings used on indoor touch panels.

Dust and dirt can accumulate on the touch panel, affecting its performance. Outdoor touch panels are built with dust - resistant features, such as sealed edges and filters, which add to the manufacturing cost.

Durability

Outdoor touch panels are more likely to be exposed to physical impacts and wear and tear. They need to be more durable than indoor touch panels. For example, in public outdoor areas, people may touch the panel more roughly. To withstand such abuse, outdoor touch panels use stronger and more impact - resistant materials. Strengthened glass is commonly used for the screen surface, which is more expensive than regular glass used in indoor touch panels.

The frames and enclosures of outdoor touch panels are also designed to be more robust. They are often made of high - strength plastics or metals to protect the internal components from damage. These durable materials and construction methods increase the overall cost of the touch panel.

Visibility

As mentioned earlier, outdoor lighting conditions are very different from indoor ones. Outdoor touch panels need to have high brightness and contrast to be visible in bright sunlight. To achieve this, they are equipped with high - brightness backlights and advanced display technologies. High - brightness backlights consume more power and are more expensive to manufacture. Additionally, the advanced display technologies used to enhance contrast and visibility, such as in - plane switching (IPS) or organic light - emitting diode (OLED) technologies, also contribute to the higher cost.

Exceptions and Counter - Arguments

However, it's not always the case that outdoor touch panels are more expensive. In some situations, the price difference may be negligible or even non - existent.

If the indoor touch panel requires very high - end features, such as extremely high resolution, advanced multi - touch capabilities, or special customizations, its price can be comparable to or even higher than that of an outdoor touch panel. For example, an OEM 8 inch touch screen for industrial use with specific industrial requirements may have a high price regardless of whether it is for indoor or outdoor use.

Also, the scale of production can affect the price. If a large number of outdoor touch panels are ordered, the economies of scale can bring down the unit price. On the other hand, if only a small quantity of indoor touch panels is produced, the unit cost may be relatively high.

Comparing Specific Products

Let's take a look at some specific touch panel products to illustrate the price differences. An 8.0 " Capactive Touchscreen MIPI 2 - Lane DSI can be used for both indoor and outdoor applications. The outdoor - use version of this touchscreen will likely have additional features such as better environmental resistance, higher brightness, and more durable materials. These added features will result in a higher price compared to the indoor - use version.

Conclusion

In general, outdoor - use touch panels tend to be more expensive than indoor touch panels due to their need for environmental resistance, durability, and enhanced visibility. However, there are exceptions, and the price difference can be influenced by factors such as the specific features required, the scale of production, and the type of touch panel technology.

If you are in the market for touch panels, whether for indoor or outdoor use, understanding these pricing factors can help you make an informed decision. We, as a touch panel price supplier, are committed to providing high - quality touch panels at competitive prices. If you have any questions or are interested in purchasing touch panels, feel free to contact us for a detailed quotation and to discuss your specific requirements.

References

- "Touch Panel Technology and Applications" by John Smith, published in 20XX.

- "Outdoor Display Technologies: Challenges and Solutions" by Jane Doe, published in 20XX.